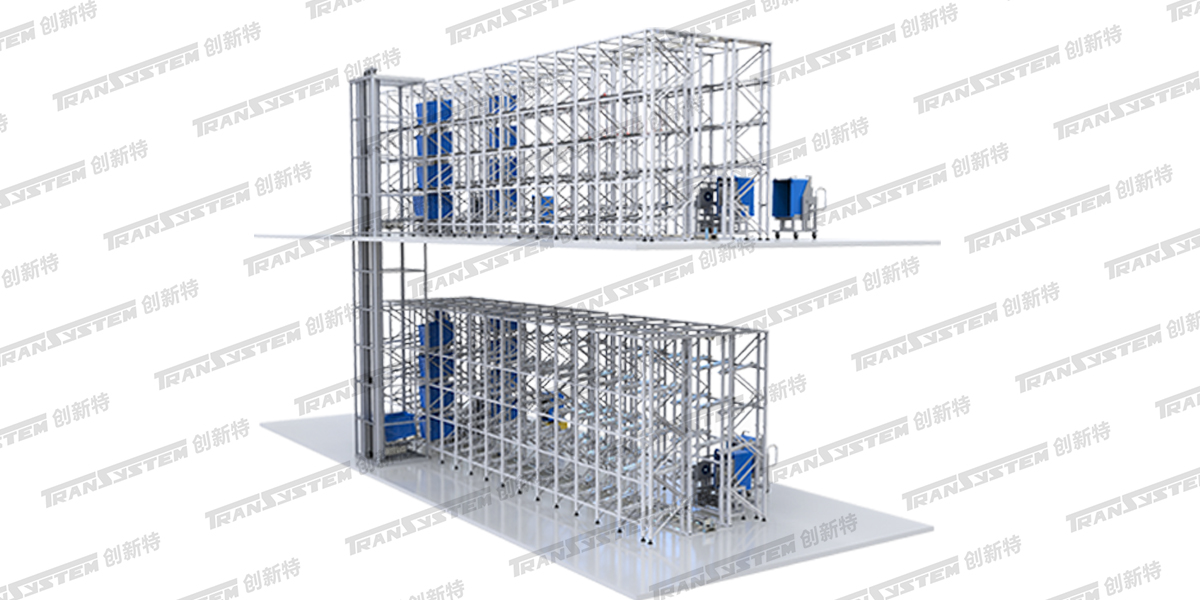

Central Buffers

Clean room class 100 (ISO-5)

-

Central Buffer

Central buffers are important pieces of a fully automatic smart factory. They maximize space utilization, and can be connected with processes to reduce bottlenecks, increase efficiency, manage and trace materials, protect material quality and combine with AGV for full automatic transport.

Specifications:

- Customizable to suit various PCB tooling, including magazine, tray, Lrack, box etc.

- Materials are stored in a highly controlled environment: clean (up to ISO-5), humidity/temp monitored, FM protected. Material management and traceability through SLC and MES.

- Customizable ports to suit various transporting trolleys and AGVs.

- High speed and precise movement for storing and retrieving, suitable in high end factories such as PCB, semiconductor industries.

- Communicates with MES, ERP to achieve I4.0. Supports SEMI SECS GEM, OPC etc.

-

Clean Room Central Buffer

Specifications:

- Cleanliness up to ISO-5.

- Highly efficient HEPA FFU.

- Sealed covers, pass box type ports.

- Connect with factory ACMV to control internal temperature/humidity.

-

Inter-floor Central Buffer

Specifications:

- Material can be transferred between inter-floor central buffers, or directly through a high lift.

- Fire standards compliant: GB, ISO etc.

-

FIFO Panel Buffer

Specifications:

- Types: FIFO (First In First Out), FILO (First In Last Out), SMART buffer (any designated panel)

- Entrance and exit of buffer can be customized to suit front and back process lines, such as conveyor height.

- Panel buffer quantity: Customizable.

- Stores NG panels rejected from processes. Also reduces bottleneck by buffering between different process line speeds.

- Customizable for panel buffer quantity. Can be combined in modules to increase buffer quantity.

- Cleanliness: HEPA filtered environment.

-

FILO Panel Buffer

Specifications:

- Types: FIFO (First In First Out), FILO (First In Last Out), SMART buffer (any designated panel).

- Entrance and exit of buffer can be customized to suit front and back process lines, such as conveyor height.

- Panel buffer quantity: Customizable.

- Stores NG panels rejected from processes. Also reduces bottleneck by buffering between different process line speeds.

- Customizable for panel buffer quantity. Can be combined in modules to increase buffer quantity.

- Cleanliness: HEPA filtered environment.

-

Smart Panel Buffer

Specifications:

- Types: FIFO (First In First Out), FILO (First In Last Out), SMART buffer (any designated panel).

- Entrance and exit of buffer can be customized to suit front and back process lines, such as conveyor height.

- Panel buffer quantity: Customizable.

- Stores NG panels rejected from processes. Also reduces bottleneck by buffering between different process line speeds.

- Customizable for panel buffer quantity. Can be combined in modules to increase buffer quantity.

- Cleanliness: HEPA filtered environment.