Inline Automation

-

Micro Ball Attach and Reflow Automation

Specifications:

- Reduce material waiting/idle time and improve efficiency.

- Reduce handling of material, and improve handling risks and quality.

- Processes of different clean room environment can be connected, improve process yield.

- MES ready with PC communication, and CCTV monitoring.

-

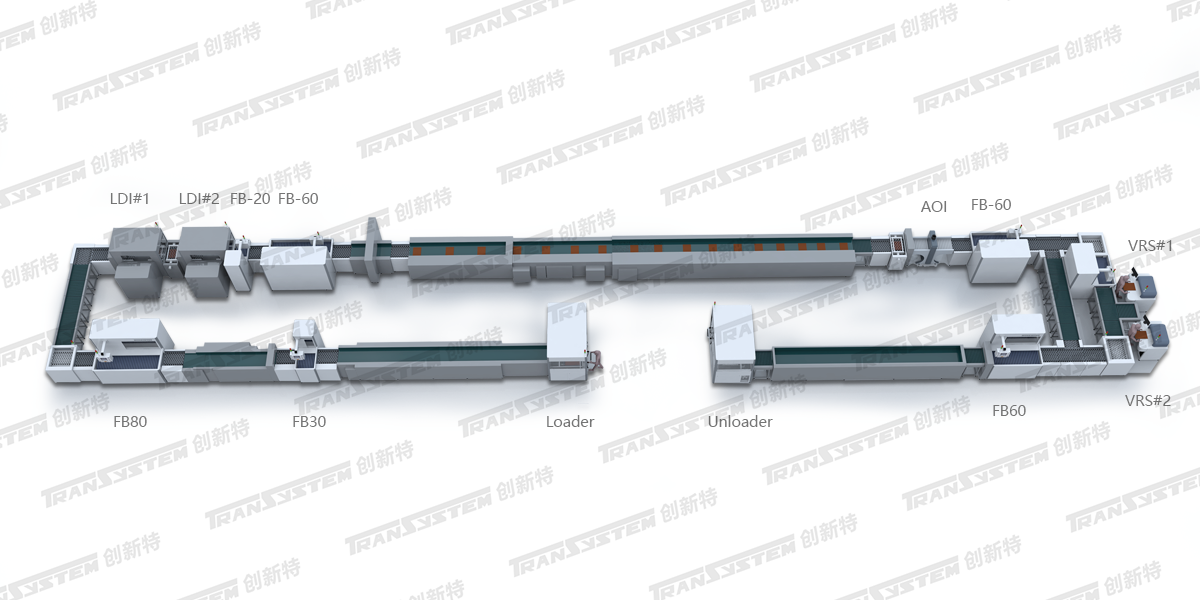

Inner Layer Inline Automation

Specifications:

- Reduce material waiting/idle time and improve efficiency.

- Reduce handling of material, and improve handling risks and quality.

- Processes of different clean room environment can be connected, improve process yield.

- MES ready with PC communication, and CCTV monitoring.

-

Outer Layer Inline Automation

Specifications:

- Reduce material waiting/idle time and improve efficiency.

- Reduce handling of material, and improve handling risks and quality.

- Processes of different clean room environment can be connected, improve process yield.

- MES ready with PC communication, and CCTV monitoring.

-

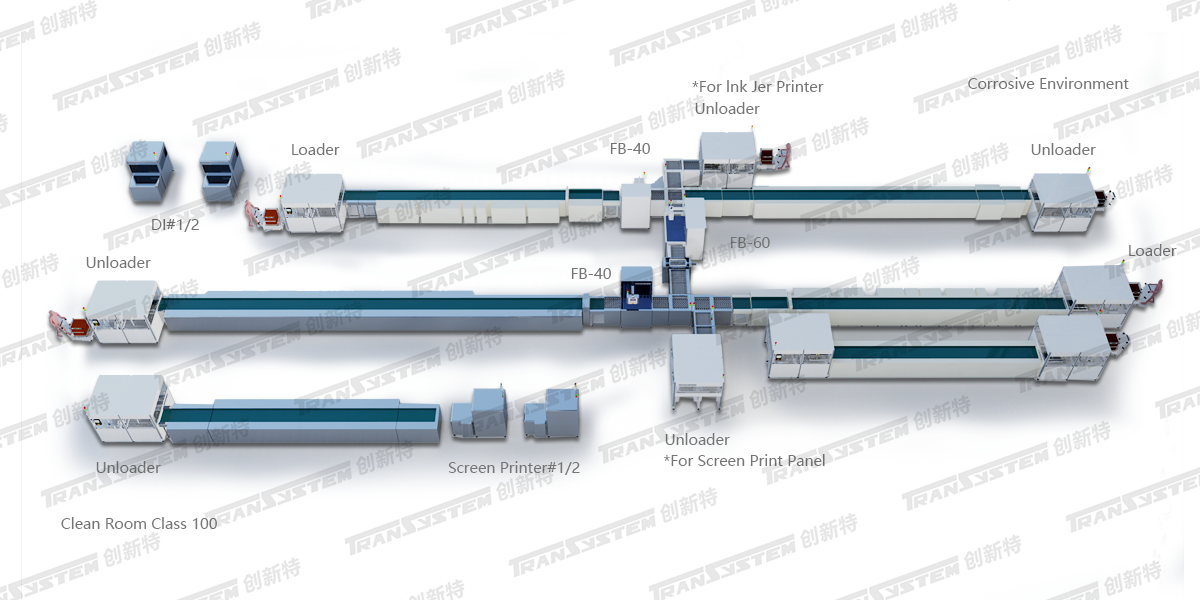

Solder Mask Inline Automation

Specifications:

- Reduce material waiting/idle time and improve efficiency.

- Reduce handling of material, and improve handling risks and quality.

- Processes of different clean room environment can be connected, improve process yield.

- MES ready with PC communication, and CCTV monitoring.

-

Pretreatment, Lamination, LDI Inline Automation

Specifications:

- Reduce material waiting/idle time and improve efficiency.

- Reduce handling of material, and improve handling risks and quality.

- Processes of different clean room environment can be connected, improve process yield.

- MES ready with PC communication, and CCTV monitoring.

-

-